P-Series Reactor System:

A High-Throughput Multi-Channel Reactor for Discovery and Process Optimization

REACTOR SYSTEM

The P-Series High-Throughput Reactor platform consists of a sophisticated multi-channel automated reaction system that has been seamlessly integrated with an SI liquid handling robot. This cutting-edge system is housed within a glovebox, providing a controlled environment for optimal performance.

A defining feature of the P-48 is the precise and independent regulation of temperature and pressure for each reactor, which allows for optimal control of the reaction conditions. This system is also capable of reliably injecting liquids or slurries under high pressures and within short time constraints, making it ideal for High Throughput Experimentation where speed and accuracy are essential. Reactions can be quenched based either on time or totalized gas uptake, allowing critical evaluations of catalyst candidates at similar if not constant conversions.

Reliable Injection & Sampling

The P-Series allows injections or reaction sampling at pressures up to 500 PSIG at 200 °C using a standard 22-gauge needle and without the need of expensive replacement components. This patent pending injection/sampling advancement incorporates a valve with very low dead volume, 1.5 uL.

Lightweight Stirrer Design

The Mid-Head Stirrer design of the P-series dramatically reduces head weight to facilitate manipulations in a glovebox. The system’s U-Shaped stir paddles provide high mass transfer coefficients (Kla value) and allow for injections directly into, or sampling from, the reaction mixture.

REACTOR MODULE OPTIONS

The P-Series reactor modules come in three reaction volumes.

Modules | P-8 | P-6 | P-4 |

|---|---|---|---|

# of Wells | 8 | 6 | 4 |

Reaction Volume | 5ml | 25ml | 50ml |

max Injection Pressure | 500 PSIG | 500 PSIG | 500 PSIG |

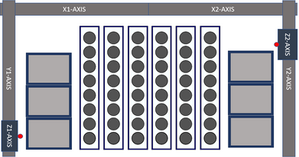

FLEXIBLE DECK CONFIGURATION

The reactor design accommodates a variety of deck layouts, depending on the amount of product desired for a particular use case (e.g., enough polymer for rheological measurements). The three reactor modules are interchangeable and fit in a single deck location. A few examples are shown below.

SOFTWARE

P-Series reactors are operated by an intuitive, yet powerful, software suite. Starting with an easy-to-use software interface, the user has the power to control the P-48 manually, run an automated process created using a drag and drop editor, or switch back and forth as needed. The data from each experiment can be conveniently exported to .xml, .json or .csv formats and processed using your software of choice to readily integrate into your existing workflows. Library “Recipes” can be imported from legacy software such as Symyx “Library Studio” .lsr files, easing the transition from systems based on legacy hardware.

APPLICATIONS

The P-48 excels in a wide variety of demanding applications:

-

Polyolefin catalyst screening with Ziegler-Natta or homogeneous catalysts

-

Hydrogenations with homogeneous and heterogeneous catalysts

-

Reactions involving challenging reagents like CO, butadiene, ethylene oxide

-

Applications where gas uptake measurements could be used as a basis for quenching.